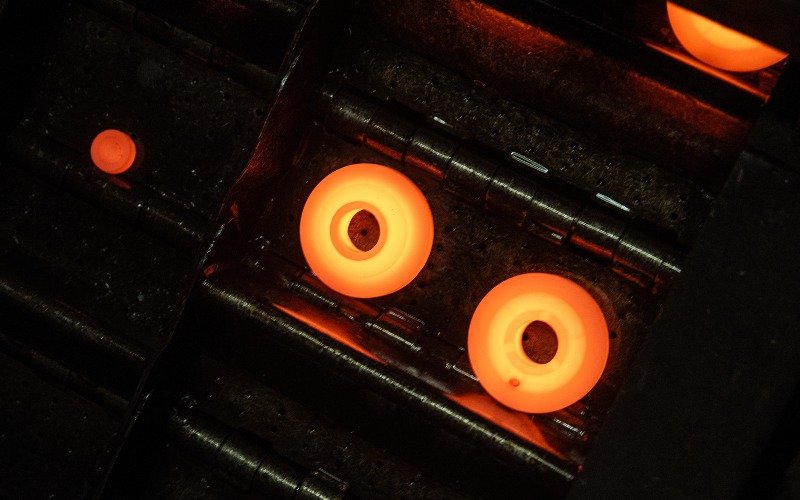

Hot forging process is performed at OMVP through high-speed horizontal HATEBUR presses.

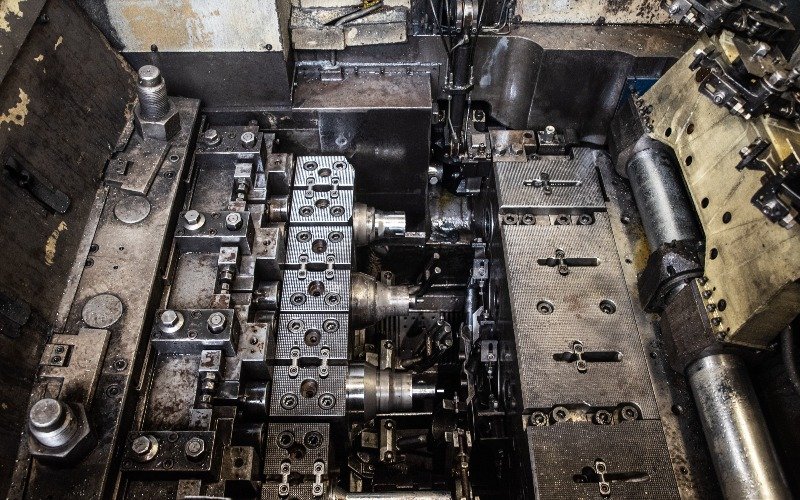

These presses are a highly efficient and automated way of manufacturing precision metal components, typically used for large-scale production.

The process is based on use of multi-stage tooling capable of performing sequential operations, such as upsetting, piercing, trimming, and coining, in a continuous cycle.

Advantages of the HATEBUR forging process:

These presses are a highly efficient and automated way of manufacturing precision metal components, typically used for large-scale production.

The process is based on use of multi-stage tooling capable of performing sequential operations, such as upsetting, piercing, trimming, and coining, in a continuous cycle.

Advantages of the HATEBUR forging process:

- High Speed and Efficiency: hundreds of parts per minute

- Precision: excellent dimensional accuracy and minimal machining requirements

- Material Utilization: optimized tooling which reduces material waste

- Versatility: production of a large variety of different automotive parts and other precision components

- Competitiveness: forming without lubricants, usage of warm rolled, untreated steel

- 2 x AMP 70L forging parts up to 150mm diameter and 4,5kg weight

- 1 x AMP 70 forging parts up to 140mm diameter and 2,6kg weight

- 1 x AMP 50 forging parts up to 92mm diameter and 1,4kg weight

- 2 x AMP 30 forging parts up to 67mm diameter and 0,4kg weight